Sunday, August 26, 2007

Scanning Electron Microscope Sem for Electron Microscopy or Atomic Force Microscope for Auger Testing & Tensile Testing.

The following is what I have:

1. X-ray Photoelectron Spectroscopy (XPS)

2. Scanning Electron Microscopy (SEM/EDAX)

3. Auger Electron Spectroscopy (AES)

4. Atomic Force Microscopy (AFM)

5. Scanning Tunneling Microscopy (STM)

6. Alpha Step

7. Tensile Tester

8. Fatigue Tester

9. Macrohardness Tester

10. Microhardness Tester

11. Wetting Balance

12. X-ray Diffractometer

13. Transmission Electron Microscopy (TEM)

14. X-ray Fluorescence (XRF)

15. Gas Chromatography Spectrometer (GCS)

16. Gas Chromatography Mass Spectrometer (GCMS)

17. Atomic Absorption Spectrometer (AAS)

18. Inductive Couple Plasma (ICP)

19. Rutherford Back Scattering (RBS)

20. Metallography facilities

21. Thermal analysis DTA/TGA/DSC

Add energy dispersive spectroscopy of x-rays (EDX) for TEM, wavelenght dispersive spectroscopy of x-rays to SEM or better add microprobe to the list, add electron energy loss spectroscopy (EELS) to TEM, add scanning transmission electron microscope (STEM with EDS/EELS), add as *No. 0*: light microscope (LM), add as *No. -1*: eye and hand (the most powerful and expensive examination and testing facilities known). BTW: EDAX is the name of a company, not of the system. The system you think of is called EDS or EDX.

Kolski bars aka Split Hopkinson pressure bars: One each for tension, compression, and torsion. And please include high speed photographic capability with more than 10 frames at about 5 microseconds each. That should take care of your next few million dollars.

After that you may want to add a facility for shock and spall testing. An 80mm gas/power gun that can accelerate the projectile to 2000m/s and a soft-recovery apparatus is the minimum. Laser diagnostics complete the package.

For low-budget items, how 'bout upgrading the SEM for automated EBSD? And please also consider adding a digital controller to your servo-hydraulic test frames so you can incorporate real-time computed variable control.

Hey, I have a professor who did his PhD thesis with that kind of equipment (basically measuring impact wave propagation in steel). He ended up building most of his own equipment (the camera was particularly nice). I imagine it took a chunk of change, but certainly not a few million. Of course he didn't have the lasers and digital controls.

Wednesday, August 8, 2007

Surface Roughness (SROIB)

I don't have the exact definition at hand, but you can find it in ANSI B46.1 - Surface Texture. Available from the American Society of Mechanical Engineers in New York. Waviness is a 'larger' feature than roughness. Roughness may be considered to be superimposed on a wavy surface.

One reference I have says - Waviness includes all irregularities whose spacing is greater than the roughness sampling length and less than the waviness sampling length.

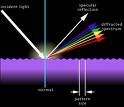

This is correct. When you measure the vertical position of a stylus translated across a surface, you see a complex graph with many possible kinds of up and down bump patterns. One way used to analyse these graphs is to make a frequency profile, using Foreir transformations, recording the frequency of the height variations and the intensity. Thus different wavelenghts may be enhanced on some samples, indicating some periodicity from a certian sized machint tool.

Don't text gives the realtive length scales for the variations named. In the literature specific recriprocal micron numbers are used.